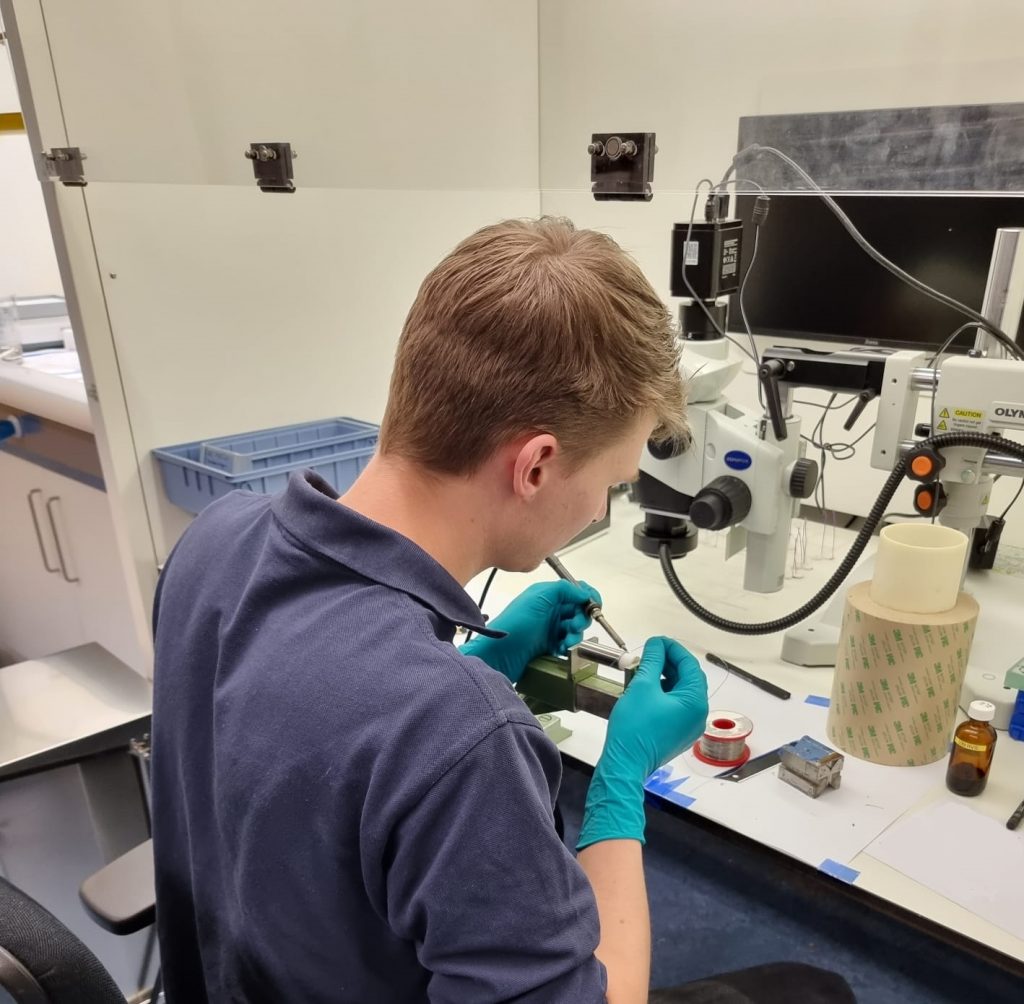

One of the services we can provide is (on-site) certified bonding and advise in bonding strategies/ tooling.

For example during the production of Mil-spec cables, Epoxy potting can be a key part during the process of enhancement of the reliability of the cables. Epoxy potting involves encapsulating cable components (such as connectors, splices, and terminations) with epoxy/ Polyurethane resin. This process creates a protective barrier that enhances the cable’s performance and longevity.

- Benefits:

- Environmental Protection: Epoxy potting seals the cable against moisture, chemicals, and contaminants. It prevents water ingress, which could lead to corrosion or electrical shorts.

- Mechanical Stability: The epoxy forms a solid, stable mass around cable components, reducing the risk of damage due to vibration, shock, or bending.

- Thermal Management: Epoxy potting helps dissipate heat generated during cable operation, maintaining optimal temperature conditions.

- Electrical Insulation: The resin insulates conductors and prevents short circuits.

- Vibration Damping: Epoxy minimizes vibrations, crucial for cables in aerospace and defense applications.

Epoxy potting is a crucial step in ensuring the reliability and longevity of hardware and cables. By protecting against environmental hazards and enhancing mechanical stability, it contributes to the success of your project and reliability of your hardware systems.